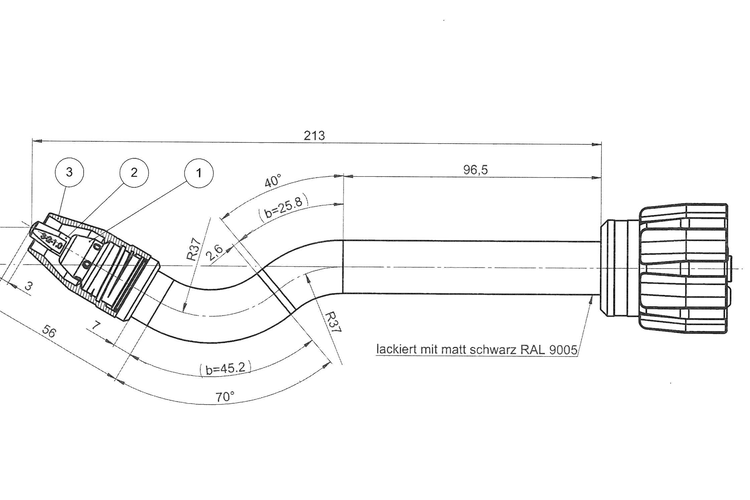

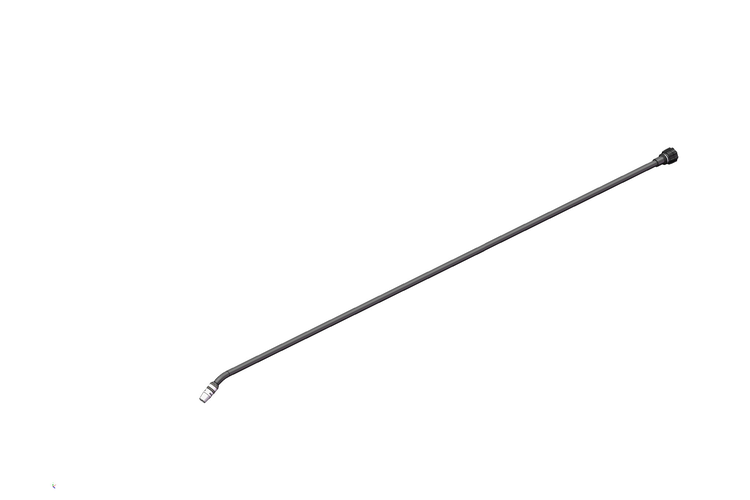

Size matters

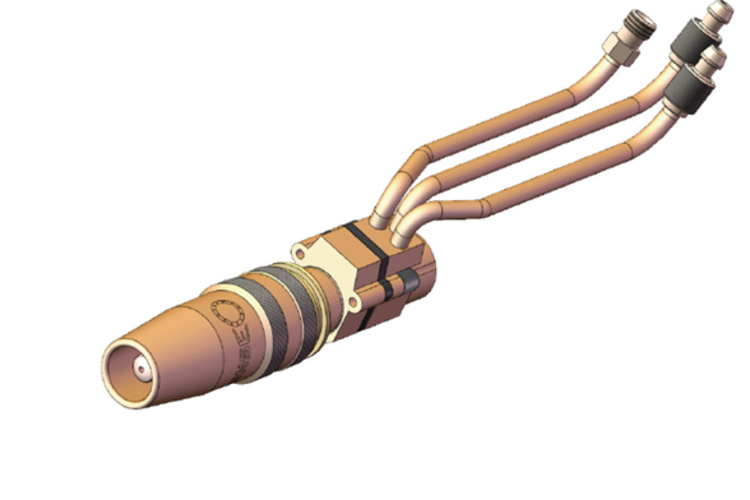

The longest burner we have ever manufactured measures an impressive two meters. By comparison, the standard length is 140 to 150 millimeters. Innovation is not just a phrase in our team, it is part of our everyday work.

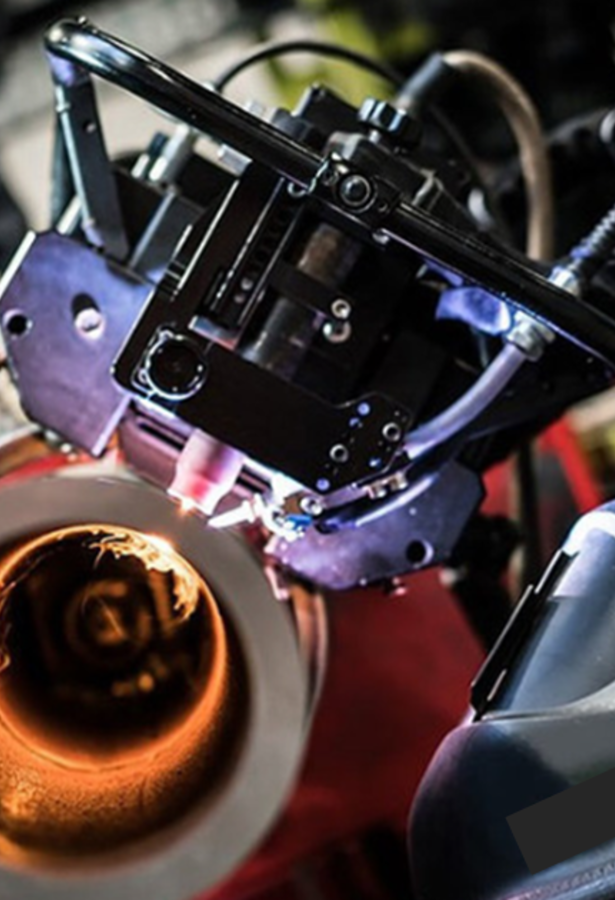

How can we realize any special solution?

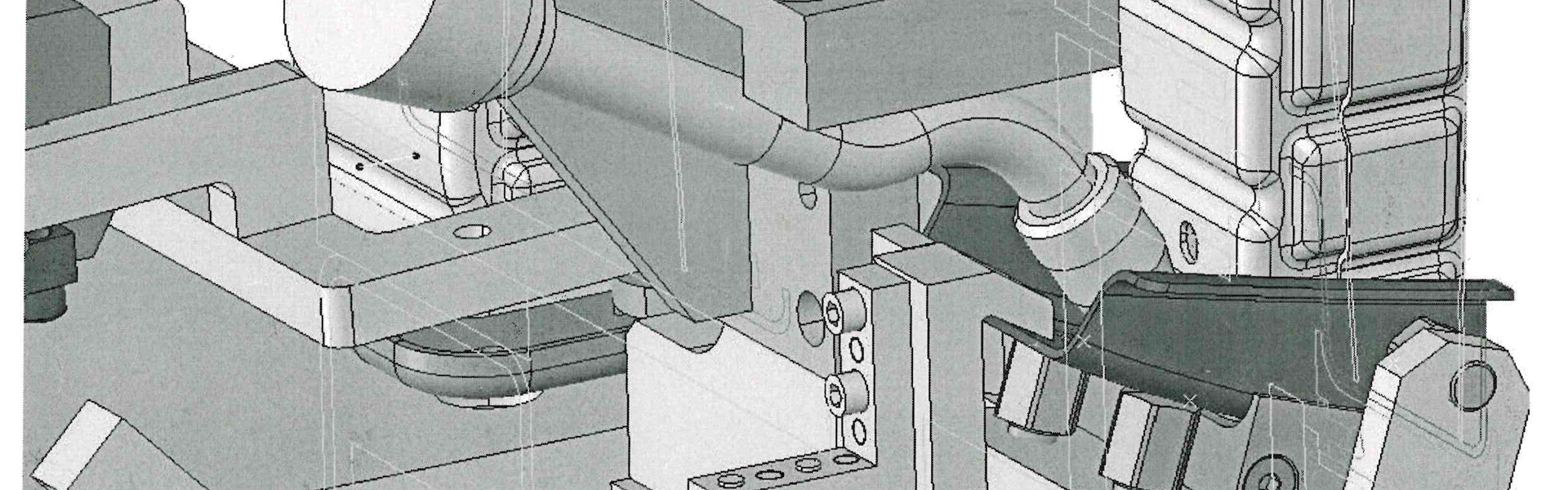

By also developing in-house operating equipment if required. For example, we have already built a flexible traversing unit that adjusts the X, Y and Z axes of each torch. This allows their tool centers (TCP) to be positioned precisely.

For the love of the welding trade

Even after decades on the market, we have never lost sight of what is important: the welders in the workshops and on the construction sites. Making their work easier is our primary goal. That's why with us you benefit at all times from uncompromisingly high quality - durable, low-maintenance, made in Germany. Challenge our expertise.